Billet Intake Runners

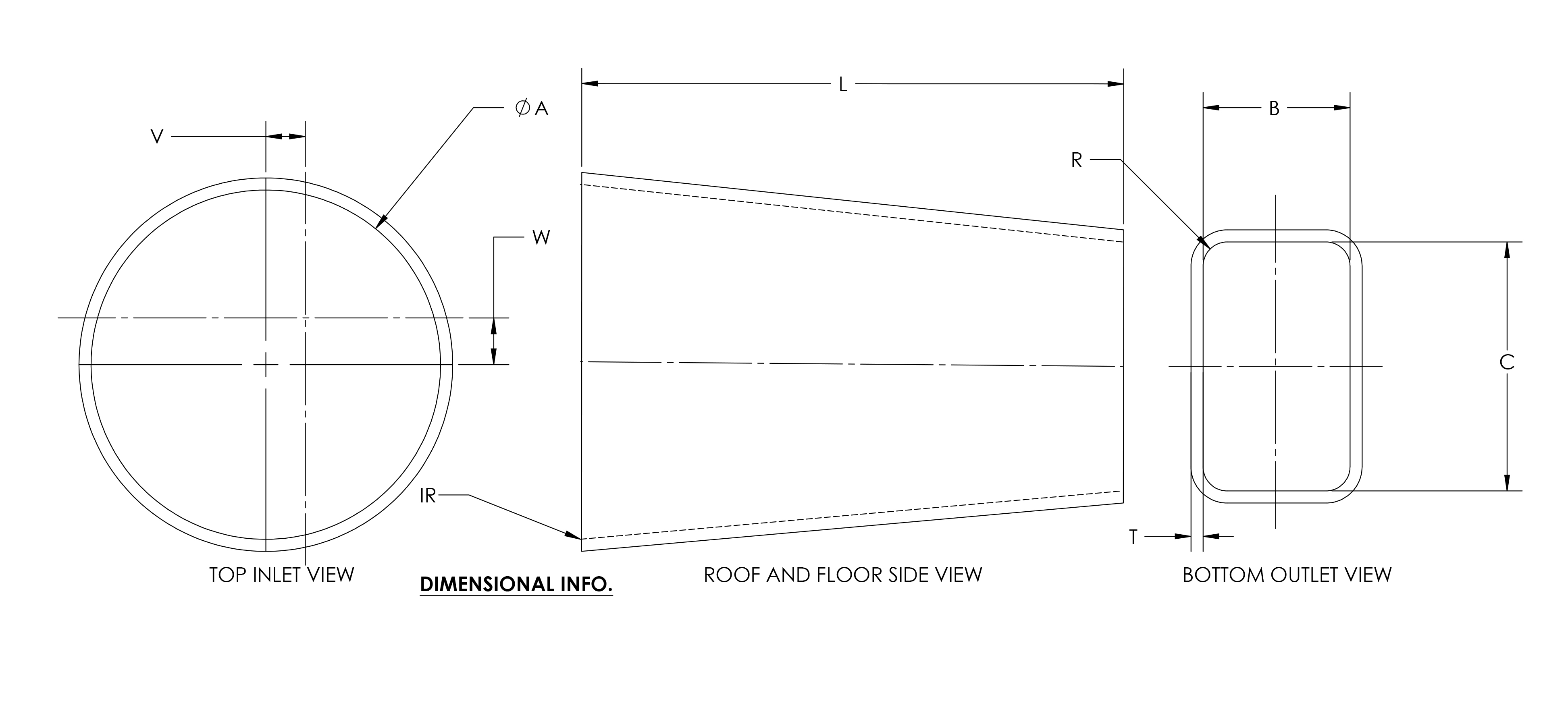

Made from 6061 billet aluminum, each set of runners is custom designed to match any type of cylinder head port configuration. CNC runners provide precise and balanced geometry to each cylinder for improved volumetric efficiency. 5-axis machining allows us to control the inside surface finish and create contours that will optimize air/fuel distribution into the cylinder head.

- Custom designed for each engine application

- Greater geometrical accuracy than sheet metal runners.

- Minimal distortion during assembly and welding

- Unlimited runner designs from round cross-section, to rectangular, oval and square ports with fillet radii.

- Nitrous bosses and curved/contoured runners also available

- Standard (individual)

- Tandem Modular

- Tandem Standard Port (non-modular)

- Billet Bank

- Contouring (Curvature)

- CNC Injector Boss’

- Lightening

- NHRA / IHRA Pro Stock

- Competition Eliminator

- Top Sportsman

- Top Dragster

- Pro Modified

- Hemi Shootout

- Truck & Tractor Pulling

- Drag Boats

- Taylor Lastor – TRE Racing Engines

- Dave Hughes – HRE Induction Specialties

- Adam Manchester – RAD Cylinder Heads

- Louis Boyd – Boyd’s Racing Engines

- Matt Bieneman – MBE Cylinder Heads and Manifolds

- Roy Johnson – NHRA Pro Stock

- Robert Hallberg – Pat Musi Performance

- Ron Hutter – Hutter Racing Engines

- Frank Cervelli – NHRA Competition Eliminator

- Charlie Watson – NHRA Comp H/A Record Holder

- Jon Bennett – Bennett Racing

- Chris Lunsford – Sheppard Race Cars

- Ron Miller – Miller Racing Engnies

- Dave Campbell – Designed Performance

- Mike Weinle – Weinle Motorsports

- Scot Slotten – Dyno-Flo

For runner orders that are 1 to 4 sets, the usual turn-around time is 7-10 business days. Factors that can increase this time are:

- Current work volume

- Complexity of the runner design

- High volume orders

- Delays in material supply

No. All billet runner orders that we produce are 100% custom to your specific application. We do not sell “off the shelf” runners like some of our competitors. However, we can machine duplicate orders of your individual runner designs. We will not sell any of your runner designs to other customers.

If the runner is made to your exact specifications, yes. The advantage of billet runners is not in the material itself but the CNC machine’s ability to create precision geometry from runner to runner and eliminate human error from hand fabrication. Many companies that make billet runners will often sell you an “off the shelf” runner that they will hand-cut and manipulate to fit your application. This adds human error to the process and will affect the overall performance of your induction system. Surface finish is also a factor, especially on the inside of the runner. A chattered surface finish not only looks bad but affects the geometry and flow characteristics of your manifold.

Because of the significant increase in cycle time and the difficulty maintaining a clean, consistent surface finish as runner size increases, we typically do not produce billet runners over 6.750 inches. We can provide you a quote on making runners in 2 sections or adding part of the runner to the flange.

When you purchase a set of billet runners, the price includes 3D modeling, programming, CNC machining, and standard ground shipping (Continental USA only). There is no extra charge for offsets, counterbores, and radii. There is an additional fee per set for nitrous injector boss’, curved intake runners, and lightening.

Yes, in addition to contoured, tandem, and billet banks. Feel free to call us for a quote on your specific application.

Please download our billet runner order form in .pdf format. This form will have all of the technical data to provide us to machine your runners.

Yes, an 80% non-refundable deposit is required for all billet intake runner orders, with the 20% balance due before shipping.

About us

Williams Engineering LLC, located in Cincinnati, OH, was founded in 2005.

Follow us on social

Get in touch with us